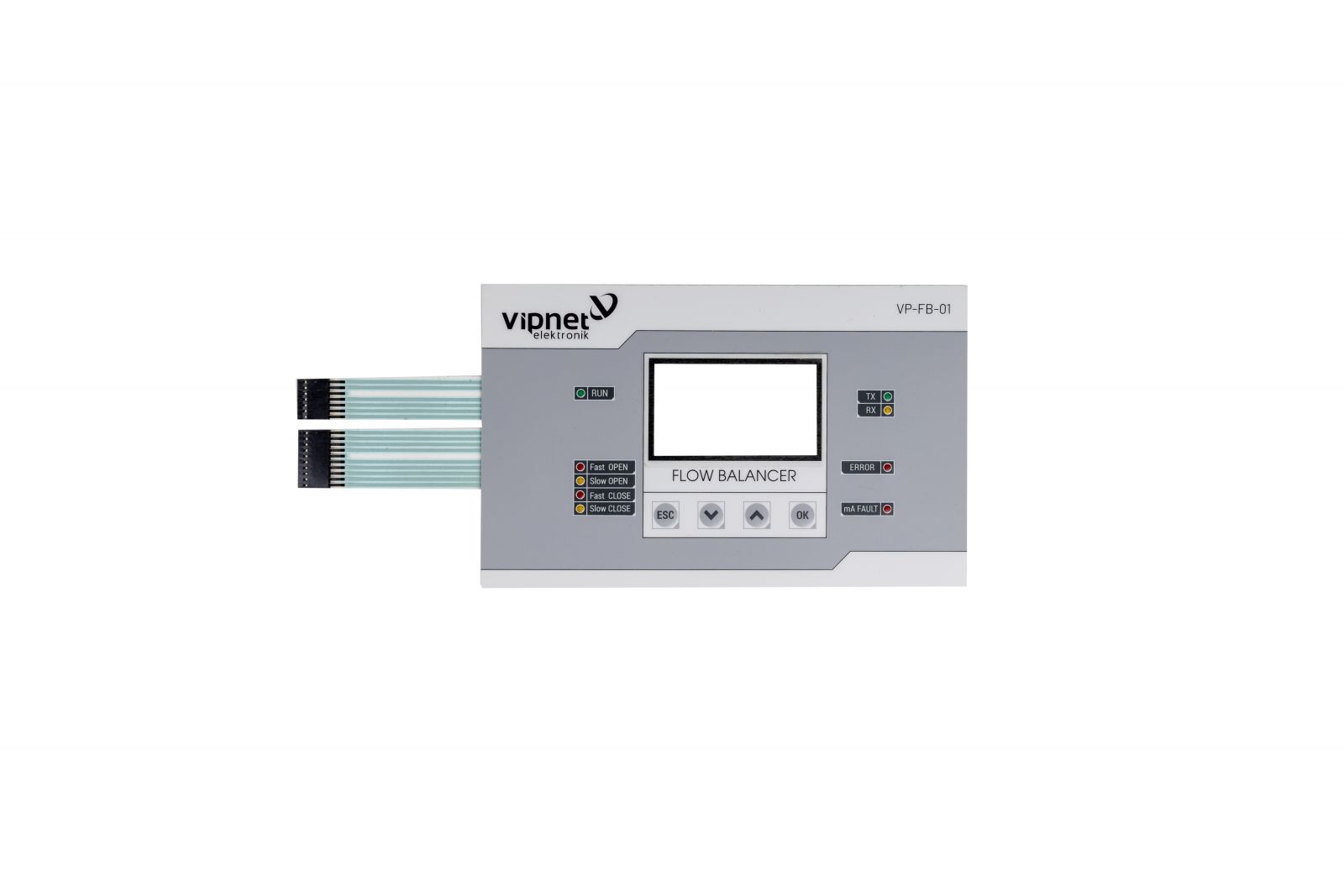

Lexan labels, also known as Lexan keypads, are a type of label produced using special printing techniques on a transparent material, applied with double-sided tape on the back. These labels are also referred to as panel labels, keypads, and membrane switches. Their primary function is to be used in the indicator panels of electronic devices, keypads, and various labels containing warning or command information. Lexan labels not only offer functionality but also provide the opportunity to highlight brand identity through their aesthetic designs. While enriching the appearance of your products, they also take on the role of representing your brand.

What is a Lexan Keypad?

A Lexan (Lexan) keypad is a durable and flexible control interface used in industrial and electronic devices. Manufactured from high-quality plastic materials such as polycarbonate or PET, these keypads are critical components that facilitate interaction between the user and the machine. The durability and flexibility derived from the nature of Lexan material allow these keypads to provide long-lasting and reliable performance even in challenging industrial environments.

Lexan (Lexan) keypads typically house a printed circuit board (PCB) on the back surface and include a graphical interface on the upper surface that the user interacts with. This structure ensures that the keypads remain thin and compact while allowing for the execution of complex functions. Additionally, due to the light permeability of Lexan material, features such as LED lighting can be easily integrated, enabling effective use of the keypads even in low-light conditions.

Manufacturing Lexan Keypads

The manufacturing of Lexan keypads is a process that requires high precision and quality. This process begins with the analysis of customer needs and includes design, production, and quality control phases. The manufacturing process generally follows these steps:

- Design and Prototyping: The keypad design is created based on customer requirements, and a prototype is produced.

- Material Selection: Lexan material suitable for the intended use is selected (polycarbonate or PET).

- Printing Process: The selected graphic design is printed on the Lexan surface using special inks.

- Circuit Printing: The electronic circuit is printed on the back surface of the keypad.

- Assembly: LEDs, metal domes, and other electronic components are assembled.

- Quality Control: The produced keypads are meticulously tested.

Advanced technology equipment and skilled craftsmanship used in Lexan keypad manufacturing ensure that the products are of high quality and long-lasting. Keypads produced specifically for industrial applications may feature waterproof and dustproof properties, providing reliable performance even in harsh working conditions.

Combining Ergonomics and Functionality in Lexan Keyboard Manufacturing

Lexan (Lexan) keyboard manufacturing goes a step beyond standard keypad production, aiming to create broader and more complex control interfaces. These keyboards are designed especially for industrial control panels, medical devices, and specialized computer systems. Ergonomics and functionality take precedence in Lexan keyboard manufacturing.

During the manufacturing process, various keyboard layouts can be applied, ranging from standard QWERTY arrangements to special function keys. The flexibility of Lexan material allows the keyboards to conform to curved or specially shaped surfaces. This feature provides a significant advantage, particularly in applications that require limited space or special design.

Advanced printing techniques used in Lexan keyboard manufacturing ensure that the keys do not wear off even after prolonged use. Moreover, specially designed metal domes placed beneath the keyboard provide tactile feedback to the user, ensuring that the correct keys are pressed even in dark environments.

Innovations in Lexan Keyboard Technology

Significant technological advancements have been made in Lexan (Lexan) keyboard manufacturing in recent years. Innovations include making keyboards thinner and lighter, increasing energy efficiency, and integrating touch technologies. For instance, some modern Lexan keyboards may include touch surfaces alongside traditional mechanical keys. These hybrid designs offer users greater flexibility and functionality.

Another important innovation is the integration of smart lighting systems into Lexan keyboards. These systems provide backlighting that can automatically adjust according to ambient light. This allows users to work comfortably even under varying light conditions. Additionally, some advanced Lexan keyboards include programmable keys that can be customized according to user preferences. This feature enhances efficiency, especially in complex industrial applications.

Lexan Switch Manufacturing: The Perfect Solution for Precise Control

Lexan (Lexan) switch manufacturing is a specialized production process designed to meet the precise control needs of industrial control systems and electronic devices. These switches can be produced in various formats, from a single button to complex control panels. The most important features of Lexan switches are their durability and precise operating principles.

In the manufacturing process, the switch design is printed on the Lexan material using special inks. Then, metal domes and conductive layers necessary for the switch's operating mechanism are placed. This structure provides both visual and tactile feedback to the user. Lexan switches are typically designed to withstand millions of actuation cycles, ensuring long-lasting and reliable use.

Customization can be done in Lexan switch manufacturing according to customer needs. For example, waterproof features can be added, different actuation forces can be applied, or special lighting solutions can be integrated. This flexibility allows Lexan switches to be used in a wide variety of industrial and commercial applications.

Innovation in Lexan Switch Design

Various innovations aimed at improving user experience are being implemented in Lexan switch manufacturing. One of these is the integration of haptic feedback technology. This technology allows users to achieve a more realistic and satisfying feel when pressing the keys. This feature is especially important in applications requiring precise control.

Another significant innovation is the increased resistance of Lexan switches to environmental factors. Next-generation Lexan switches have been made more resistant to extreme temperatures, moisture, and chemicals. This advancement allows Lexan switches to be used more safely in challenging industrial environments, such as petrochemical plants and food processing factories. Furthermore, some Lexan switch models are now equipped with antimicrobial properties, making them an ideal solution for applications in the healthcare sector.

Lexan Switch Team

The manufacturing of Lexan switch teams refers to the process of assembling multiple switches into a single control unit. These teams are typically designed for complex machine controls, industrial automation systems, or specialized electronic devices. Lexan switch teams offer users multiple control options while also providing ease of assembly and maintenance.

In the manufacturing process, the general design of the switch team is created according to customer requirements. This design includes the positioning, functions, and overall interface layout of the switches. Then, the Lexan keypad manufacturing process is applied to each switch. Finally, all switches are assembled onto a single PCB, and the necessary connections are made.

One of the most important advantages of Lexan switch team manufacturing is the customization option. Customers can choose colors and designs that align with their brand identity, add special functions, and even define the overall shape of the team to suit their products. This flexibility makes Lexan switch teams a preferred choice across a wide range of industries.

The Future of Lexan Switch Teams

The Lexan switch team manufacturing industry is evolving in parallel with the trends of Industry 4.0 and IoT (Internet of Things). In the future, it is anticipated that Lexan switch teams will become smarter and more connected. For example, these teams may have remote monitoring and control features, enabling more efficient management of industrial processes.

Additionally, the integration of artificial intelligence and machine learning technologies into Lexan switch teams is among the expected developments. This way, switch teams can learn user habits and optimize operations. For instance, a Lexan switch team used in a factory setting could analyze production processes to highlight the most frequently used functions or identify potential issues in advance.

Lexan Keypads

Lexan keypads have a wide range of applications across various sectors of the industry. These durable and flexible control interfaces are particularly preferred in environments where challenging working conditions prevail. For example, Lexan keypads frequently appear in machine control panels used in heavy industry facilities. Their resistance to factors such as dust, moisture, and high temperatures makes Lexan keypads an ideal choice in these environments.

The medical sector is another significant application area for Lexan keypads. These keypads used in hospital equipment, laboratory devices, and portable medical devices stand out with their easy-to-clean and sterilizable features. Additionally, Lexan keypads are preferred in operating room equipment that requires precise control. This allows surgeons and healthcare personnel to have reliable and precise control during critical operations.

Sustainability and Lexan Keypad Production

Today, sustainability has become an important issue in Lexan keypad manufacturing, as in all industries. Manufacturers are increasingly striving to use environmentally friendly materials and develop energy-efficient production processes. For example, some manufacturers have started using recycled polycarbonate or less harmful chemicals such as water-based inks in their production processes.

Moreover, the long lifespan of Lexan keypads is an important advantage in terms of sustainability. The durability of these products reduces the frequency of their replacement, thereby decreasing the amount of electronic waste. In the future, Lexan keypad manufacturers are expected to focus more on topics such as product lifecycle management and recycling programs.

Lexan keypads, Lexan keyboards, Lexan switches, and Lexan switch teams continue to provide indispensable solutions for industrial control systems and electronic devices. The development of these technologies not only increases the efficiency and functionality of products but also opens the door to new innovations. With a focus on user experience and sustainability, Lexan keypads are anticipated to play an even more significant role in the industrial world in the coming years.

What is a Lexan Label?

A Lexan label is a type of label made from durable polycarbonate material and is commonly used in electronic devices. These labels are produced with special printing techniques on the transparent structure of the material, and double-sided adhesive tape is often added to the back. Lexan labels stand out for their long lifespan and resistance to wear and environmental factors. Additionally, due to their light transmission and transparency, they are widely used in various industries. Lexan labels are an attractive option aesthetically as well, emphasizing the identity of brands both functionally and visually.

Lexan labels are typically used in keypads, control panels, and displays of various electronic devices. Suitable for both indoor and outdoor applications, these labels are frequently preferred in industrial settings due to their resistance to environmental factors. Their durability against heat, moisture, water, and UV rays contributes to the longevity of the devices they are used on.

Difference Between Lexan Labels and Lexan Keypads

The primary difference between Lexan labels and Lexan keypads lies in their purposes and functional properties. A Lexan label is generally a print on transparent polycarbonate that contains identification information for devices. While these labels are used to display logos, usage instructions, warnings, or technical specifications of a device, Lexan keypads function as a control interface for user interaction. Lexan keypads work in conjunction with electronic circuits located under the keys, transmitting user commands to the device.

While Lexan labels generally serve as a complementary element to a device’s appearance, Lexan keypads directly interact with the device's operating mechanism. Keypads allow users to control the device and give various commands, while Lexan labels provide information about the device's usage. Both products benefit from the durability of polycarbonate, but their functions and application areas differ.

Applications of Lexan Labels

Lexan labels, with their durable structure and aesthetic design, have a wide range of applications. They are commonly found on electronic devices, control panels, medical equipment, and industrial machinery. Due to their resistance to harsh environmental conditions, they are also frequently used in outdoor applications. In production machines, vehicle control panels, household appliances, and the automotive industry, Lexan labels help increase brand awareness by providing long-lasting usage.

Lexan labels are also quite common in medical devices. Critical information and warnings on the device are conveyed to the user clearly and safely through these labels. Their resistance to water and chemicals, making them suitable for sterilization processes, is one of the main reasons why Lexan labels are preferred in the healthcare sector. Furthermore, when used with LED lights, their transparency provides an aesthetic appearance, giving the device a modern and sleek design.

Lexan Labels in Industrial Applications

In industrial environments, where machines and equipment are used intensively, the need for durable and long-lasting labels increases. In this context, Lexan labels are designed to withstand the harsh conditions of heavy industry. Their resistance to scratches, wear, heat, and chemical substances makes these labels indispensable for industrial machines and control systems. Additionally, some special production versions offer extra protection against water and dust.

Another advantage of Lexan labels is their customizability. Manufacturers can easily print various information, from brand logos to specific technical details, on Lexan labels according to their needs. This provides a solution that meets both the functional and aesthetic requirements of the device or machine.